PRODUCTS

CONTACT US

Mobile Number: 18926501143

Mobile Number: 13689505165

101, Building 1, No. 8 Fangxing Road, Longdong Community, Baolong Street, Longgang District, Shenzhen

PVDF Series

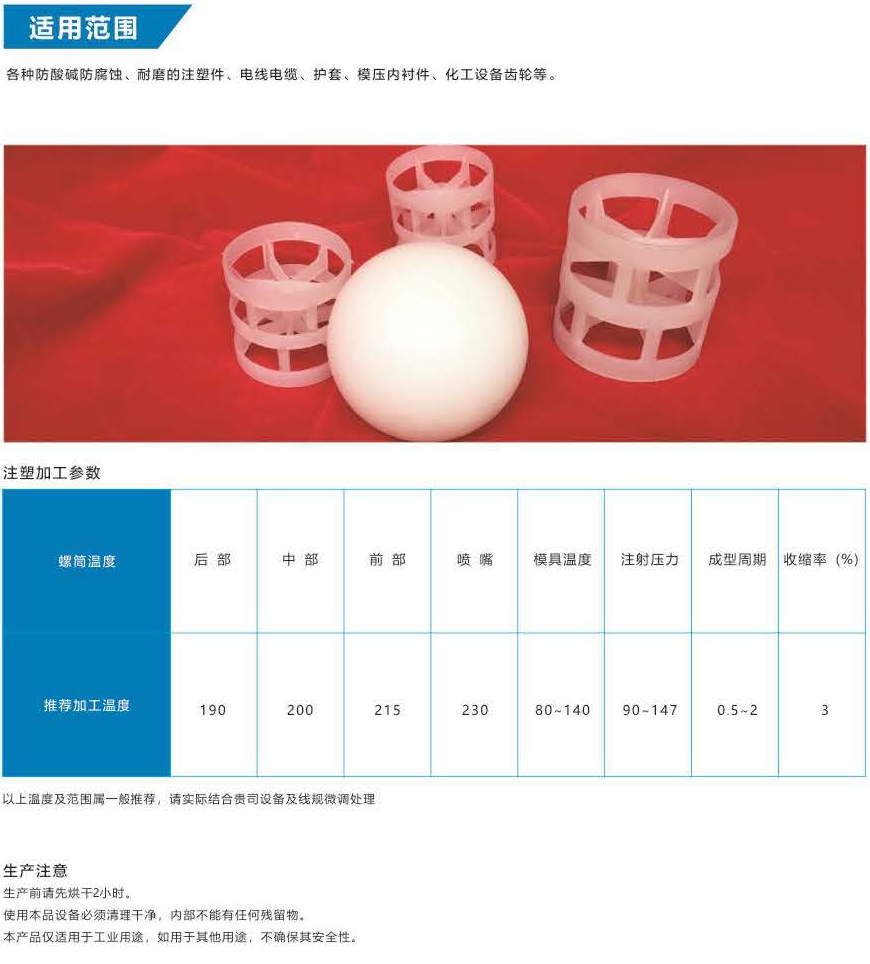

Introduction of 【PVDF】 PVDF is a PVDF meltable fluorocarbon resin for coating formed by homopolymerization of vinylidene fluoride (VDF) with a purity of ≥ 99.99%. There are 70% PVDF resin made of fluorocarbon coating by spraying or roller coating process by baking the film has unparalleled super weather resistance and processing performance. Fully comply with the United States building materials standard AAMA2605 and the People's Republic of China industry standards HG/T3793-2005. PVDF not only has strong abrasion resistance and impact resistance, but also has high anti-fading and anti-ultraviolet properties in extremely harsh and harsh environments. PVDF is the second largest product in the production of fluoroplastics, with a global annual production capacity of more than 53000 tons. <br />Characteristics of PVDF] 1. Fluorinated resin (commonly known as thermoplastic Teflon) that can be injected and exited. 2. Excellent chemical resistance. 3. Wear resistance, high mechanical strength and toughness. 4, weather resistance, anti ultraviolet and nuclear rays. 5, good heat resistance and high dielectric strength.

Product Category:

PVDF Series

Contact Us

- DESCRIPTION

-

shenzhen teflon new materials technology limited company specializing in the production of pvdf products, stable supply, national contact phone number: 18926501143, 13689505165, contact person: wu sheng, welcome the need for friends telephone contact.

PVDF (polyvinylidene fluoride) has the strongest toughness, low friction coefficient, strong corrosion resistance, aging resistance, weather resistance, good radiation resistance and so on. Polyvinylidene fluoride (PVDF) pellets | alias: polyvinylidene fluoride; Fluororesin -2;F2;F26

英文名 polyvinylidene fluoride;PVDF;fluororesin-2

physical and chemical properties

Fluororesin -2 has a relative density of 1.75-1.78, a glass transition temperature of -39°C, an embrittlement temperature of -62°C or less, a melting point of 144°C, and a thermal decomposition temperature of 320°C or more.

The long-term use temperature is -40~125 ℃, the processing temperature range from the melting point to the decomposition temperature is wide, the processing temperature is low, the melt viscosity is small, and it is easy to process.

The mechanical strength of F26 is the most superior product in fluorine resin, and it can still maintain good strength under certain temperature and pressure. High tensile strength. Good impact strength, good toughness; High hardness and good wear resistance; Anti-creep is also one of the best fluororesins. Under a load of 9.8 Mpa, after 100h, the creep elongation at normal temperature is only 2.2, and it is 7% at 100 ℃.

F26 has outstanding UV resistance and weathering resistance, and its products will not be brittle and cracked when placed outdoors for 1. 20 years. The radiation resistance is also outstanding, and there is no serious decline in performance after 3 × 108 lats r-ray irradiation. Excellent electrical insulation performance, dielectric constant (60~106Hz) as high as 6.0~8.0; dielectric loss tangent angle is also larger, between 0.04~0.2; volume resistivity is slightly lower, 3 x 1012 Ω.cm, with piezoelectric and pyroelectric.

F26 has good chemical stability and is not corroded by acid, alkali, strong oxidant and halogen at room temperature. General organic solvents have no effect on it. Only a few chemicals such as fuming sulfuric acid, strong alkali, ketone and ether can swell or partially dissolve it. Strong polar organic solvents such as dimethyl acetamide and dimethyl sulfoxide can dissolve it into colloidal solution. In addition, the water absorption at 80 ° C. is only 0.03; permeability to chlorine gas is also the smallest among fluororesins.

PVDF Technical Parameters Physical Performance Specific Gravity (g/CM3) 1.75~1.79 Melting point (℃) 160~170 Mechanical properties Tensile strength (2 ℃)> 30~50 Elongation at break (23 ℃) 50~250 Compressive strength (23 ℃-max) 50~100 Hardness 70~80 coefficient of dynamic friction 0.3 Thermal performance Continuous maximum service temperature (℃) 125 Thermal deformation temperature (1.8ZMPa) 84 Linear expansion coefficient (temperature range) 7~14 Electrical Performance Volume resistance rate (23 ℃ 5OXPH) 2 × 10 Insulation breakdown voltage 3.2mm thick 12 dielectric constant 7 Dielectric loss tangent (106Hz) <0.1

PVDF

previous page