ABOUTUS TIEFULONG

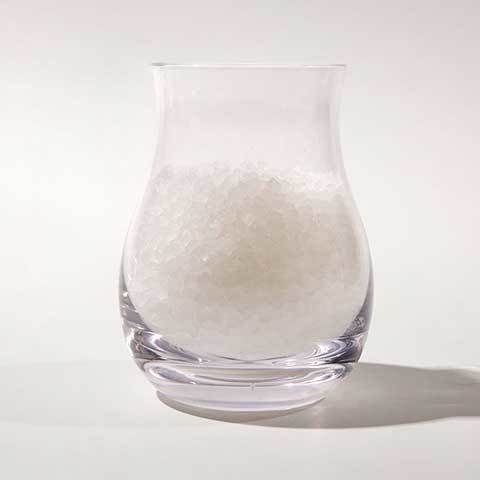

Shenzhen Teflon New Material Technology Co., Ltd. was founded in 2014, with more than 10 employees and an annual turnover of 120 million. The company specializes in manufacturing fluorine plastic raw materials, the main products are PFA, PVDF, ETFE, FEP, etc. Widely used in household appliances, communications, aerospace, construction, automobiles, new energy, aluminum profiles, aluminum curtain walls, aluminum veneer and industrial anti-corrosion spraying fields; With a wide range of sales outlets, the company is a leading enterprise in the field of fluoropolymer new materials and a manufacturer of fusible polytetrafluoroethylene (PFA) in China.

10+ professional talents

Deep farming industry

Annual turnover exceeding

The area of 150,00 square

PRODUCTS

Industry Application

GLOBAL PARTNERS

NEWS

Application and Performance Advantages of PTFE Gasket

Plasticizing process route of PFA particles

Fluorine plastic slitting machine common questions and answers

Research and development of recycled fluoroplastics will continue to develop in the future