PRODUCTS

CONTACT US

Mobile Number: 18926501143

Mobile Number: 13689505165

101, Building 1, No. 8 Fangxing Road, Longdong Community, Baolong Street, Longgang District, Shenzhen

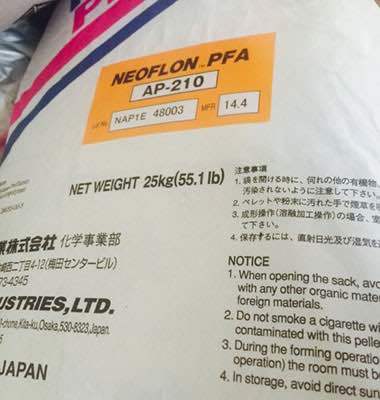

PFA Granule

Introduction of 【PFA】 PFA plastic is a copolymer of a small amount of perfluoropropyl perfluorovinyl ether and polytetrafluoroethylene. The melt cohesiveness is enhanced, the solution viscosity is reduced, and the performance is unchanged compared with PTFE. This kind of resin can be directly processed into products by ordinary thermoplastic molding methods. Suitable for the production of corrosion-resistant parts, anti-wear parts, seals, insulation and medical equipment parts, high-temperature wires, cable insulation, anti-corrosion equipment, sealing materials, pump valve bushings, and chemical containers.<br />Characteristics of PFA] 1. Crystalline material, moisture absorption is small. It can be processed into products by common thermoplastic processing methods. 2. Suitable for the production of corrosion-resistant parts, anti-wear parts, seals, insulation parts and medical equipment parts. 3. High temperature wire, cable insulation layer, anti-corrosion equipment, sealing material, pump valve bushing, and chemical container.

Product Category:

Products

PFA Series

Contact Us

- DESCRIPTION

-

1, PFA (soluble polytetrafluoroethylene) heat resistance, cold resistance, chemical stability, mechanical properties, insulation, self-lubricating, folding resistance, excellent cracking resistance;

2. Scope of application: At present, it is mainly used for anti-corrosion and anti-acid and alkali injection molding parts, high-temperature wire and cable, anti-acid and alkali lining parts, blow molding products, etc.

PFA Technical Parameters Physical Performance Specific Gravity (g/CM3) 2.12~2.17 Melting point (℃) 302~312 Mechanical properties Tensile strength (2 ℃)> 27~29 Elongation at break (23 ℃) 250~300 Compressive strength (23 ℃-max) 16.7 Hardness 60 coefficient of dynamic friction 0.2 Thermal performance Continuous maximum service temperature (℃) 250 Thermal deformation temperature (1.8ZMPa) 47 Linear expansion coefficient (temperature range) 12 12~100 Electrical Performance Volume resistance rate (23 ℃ 5OXPH) >1018 Insulation breakdown voltage 3.2mm thick 20 dielectric constant 2.1 Dielectric loss tangent (106Hz) <0.0003

PFA

previous page

previous page

next page